It sounds abstract, maybe even like mumbo-jumbo to some, but for industries powering our technological revolution, it’s a very real aspect of innovation. It’s the thing that’s making your smartphone and car engine control units tick as well as what powers the satellites orbiting our Earth. But what is PCBA and why anyone should care?

What is PCBA?

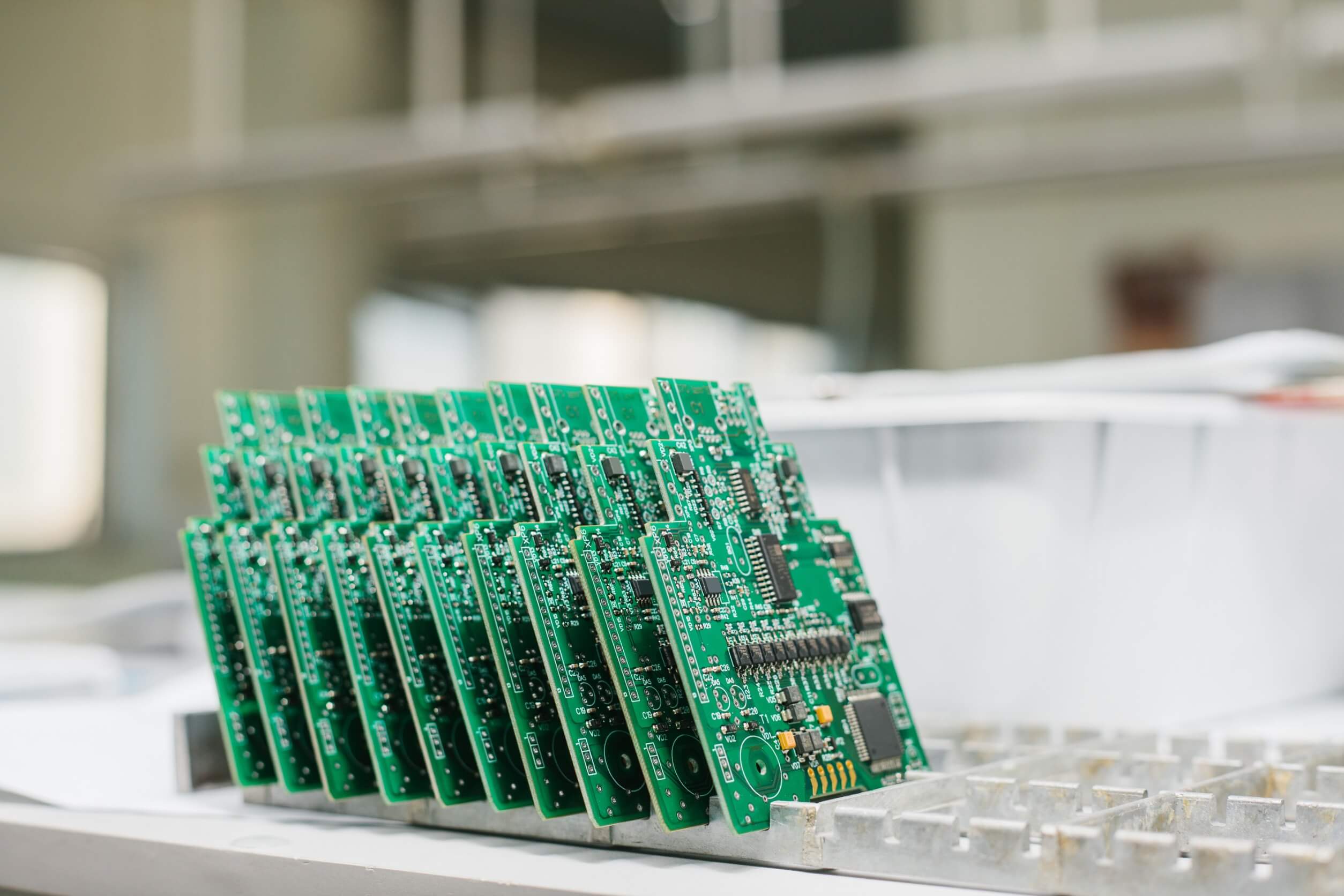

PCB assembly is the process of soldering and mounting electronic components onto a printed circuit board (PCB). It’s like adding the critical “muscle and nerve” to the PCB “skeleton.” This assembly process ensures that the end product – a computer motherboard, a smartwatch, or your WiFi router – functions exactly as intended.

Why is PCB assembly important?

Imagine building a puzzle. The PCB is the board where all the pieces of the puzzle fit. The pieces themselves, like resistors, capacitors, and integrated circuits, come together during the PCB assembly. If properly done, these assemblies turn blank boards into intelligent systems capable of controlling machines or processing data. Without PCB assembly, technological innovations we have become accustomed to wouldn’t be possible.

But, like any craft, PCB assembly has evolved. It has embraced automation and advanced design methodologies to meet the increasing complexity of modern devices. Now, emerging trends are pushing the boundaries even further.

Emerging Trends in PCBA

Take a moment to imagine this scenario. A small, mid-sized electronics manufacturer gazes at the growing consumer demands for energy-efficient electronics with advanced functionality. The challenge is how to stay competitive without losing sight of reliability and quality. This is where understanding trends in PCB assembly can make or break the game. Here’s how PCB assembly is changing the landscape for manufacturers and users alike.

- Miniaturization of Components

Gone are the days when electronic devices demanded suitcase-sized space. From wearables to drones, the cry is unanimous – make it smaller but smarter! The miniaturization of components has become not just a trend, but a necessity.

How does this impact PCB assembly?

Advanced techniques such as surface mount technology (SMT) are now common. SMT allows components to be mounted directly onto the surface of PCBs, reducing the space required and making it easier to assemble complex, multi-layered boards. However, this rise in compact designs also means greater precision and better quality control during the assembly process are imperative.

- Eco-Friendly Manufacturing

The world’s demand for electronics is rising, but so is the concern about its environmental impact. E-waste is expected to reach 75 million metric tons by 2030, and much of it stems from old manufacturing practices that prioritize efficiency over sustainability.

Today, eco-friendly PCB assembly processes are gaining importance. This includes lead-free soldering and the use of recyclable materials in circuit boards. Manufacturers are also turning to renewable energy sources to power their production lines, reducing their carbon footprint.

Ask yourself – what’s the price of innovation if it costs us the planet?

- Adaptation to IoT-Compatible Designs

Everything-the refrigerator, fitness tracker, lightbulb-may speak to one another through shared networks under the IoT. So for seamless function of connectivity, PCBs should aim for lightweight architecture and low power consumption.

IoT-compatible PCBs and assemblies now focus on wireless communication modules, sensors, and energy storage components. They serve a world in which data is king and interconnectivity reigns supreme. For manufacturers, this means adapting PCB assembly workflows to accommodate the requirements of IoT devices.

Wouldn’t you want to stay relevant in an IoT-driven economy?

- Advanced Materials and Flexibility

Here’s a thought experiment – how flexible is your smartphone? It’s an odd question, but foldable and flexible electronics are increasingly taking over the consumer market. Flexible printed circuit boards (FPCBs), made of such malleable materials as polyimide, is enabling a new class of products.

These boards are not just a fad; they are the gateway to bendable displays, wearable electronics, and smart clothing. Again, their production creates new challenges to soldering techniques, resistance to heat, and durability. For the PCB assembly manufacturer, innovation is no longer a choice; it’s an obligation.

- 5G Implementation

Imagine the searing speed of 5G networks and the multifarious new devices they enable – from autonomous automobiles to AR/VR-enabled gadgets. For users, 5G is an all-benefit proposition. For manufacturers, it is a complicated affair.

Specialized high frequency PCBs drives 5G-enabled devices into uncharted regions for traditional methods of PCBA. Designers and manufacturers alike are using laminates that help them ride through high-speed domains, low-loss materials, and ultra-capacitance decoupling technologies.

The take away? Manufacturers of PCB assembly who align with 5G rollouts position themselves at the head of progress.

Conclusion

The future of PCBA is one of possibility, but only for those willing to rise to the task. It may be the alignment with sustainability goals or entirely rethinking the materials, PCB assemblies hold the key to much of our shared digital future.

But the deeper truth is that innovation in PCB assembly matters not because technology demands it, but because our world depends on it. Transparent supply chains, interconnected IoT devices, and sustainable practices aren’t just trends – they are promises of a better tomorrow.

Take a closer look at your phone, your smartwatch, or even the car you drive. Every one of them tells a story. Behind it? A printed circuit board that carries not just power, but a vision for what’s possible!

Leave a Reply