It is very necessary when conducting Electrical Wiring in a Metal Building, there are some important aspects that one needs to consider before doing the wiring. Electrical installations in a metal building are quite complex regardless of whether it is a warehouse, a workshop, or an agricultural building. Failure during planning or in the implementation of proper construction design can result in expensive work to correct or even dangerous situations. It is possible to form the right strategy and receive assistance from qualified specialists such as SMA Estimating LLC and avoid these mistakes.

Here is a step-by-step guide to how to correctly install electrical wiring with minimal mistakes and hazards.

Why Is Electrical Wiring in a Metal Building Special?

Unlike traditional buildings, metal structures pose unique challenges for electrical installations:

Conduction Risks: Metal forms can highly possibly provide an easy way through which lightning can find its way in the form of a short circuit or a direct shocking effect.

Temperature Changes: High-temperature variations also make the insulation of the wires wear off much faster.

Durability Needs: Wiring has to endure external conditions such as humidity and vibrations.

Read the instructions carefully and strictly follow these preparation steps to avoid any issues during setting up.

Step 1: Think of the Electrical Plan

- However, before doing the wiring, you must prepare a proper electrical layout map of the project in mind.

- Locate all appliances, switches, lamps, fans, exhausts, and any electrically driven equipment that needs power.

- Decide what amount of amperage is necessary to not overload circuits.

- Determine how the conduit will lay along the walls or the ceilings.

- Employing Electrical Estimating Services allows you to find out the actual costs of the materials and labor. SMA Estimating LLC does this well and provides accurate estimates.

Step 2: Decide on the Right Material

- When choosing wiring materials, use durable ones to meet all the set building code requirements.

- Utilize metal conduit to guard wiring from contact with sharp edges and other harmful sources.

- There should be an option for the wires used with a high-temperature resistance just in case of a degradation process.

- Houses in the area of high humidity should incorporate moisture lock boxes and fittings if possible.

- A Metal Building Estimator can help you with how much and what type and kind of material you should use.

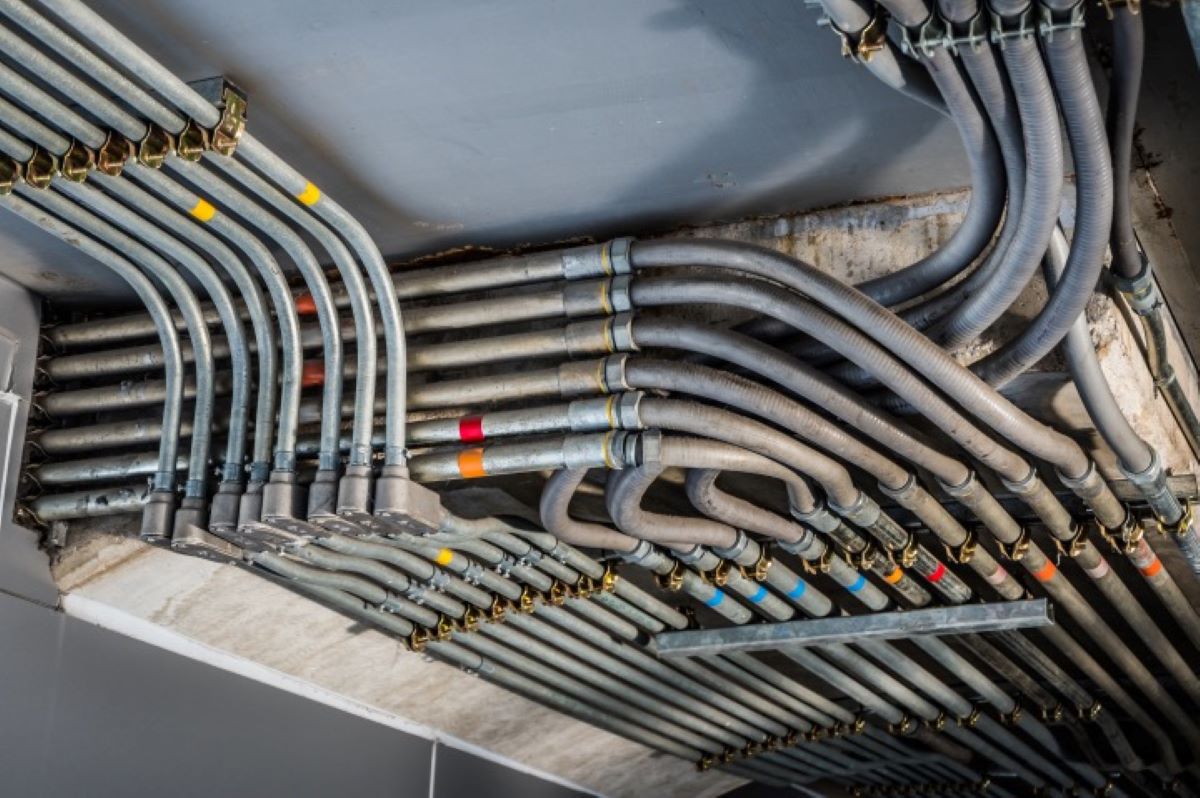

Step 3: Install Conduit Pipes

- Conduit pipes protect electric cables and minimize the chances of coming into contact with something else.

- Anchor the conduit firmly to metal walls or frames by using brackets.

- For the areas where bending is allowed, rigid conduit should not be used but instead flexible conduit should be used.

- All the conduit joints must be well sealed in a way that they do not allow dust or moisture inside.

The installation of conduits is a worthy investment since it reduces the chances of accidents more so in the wiring system and at the same time enhances the functioning of the conduits so that they may have long-lasting working time.

Step 4: Pull the Wires

- Now that you have the conduit, you can then proceed to pull the wires.

- A fish tape should also be employed to pull the wires through the conduit.

- Provide labels for each wire such that you can easily recognize that it is being used for lighting, outlets, or equipment.

- Do not over-saturate the conduit that can carry some amount of load now to make way for future expansion.

In this step, the accurate calculation can be supplemented with the help of relevant Electrical Estimating Services.

Step 5: Install Junction Boxes and Fixtures

- Junction boxes are important as they ensure that wires are well joined firmly.

- Some guidelines include placing junction boxes at points where they would be easy to reach if they are required to be censored.

- Double-check that the boxes can ground to the metal frame.

- Finally put in the lights and fixtures where required, the switches and outlets following your layout plan.

Step 6: Test and Inspect

- It is advisable to check the wiring system cautiously well before powering up the system.

- To check continuity and proper grounding, use a multimeter.

- Check the connection to make sure there is no loose wire in any of the fixtures.

- Use local standards and electrical codes to verify compliance.

A competent group of Metal Building Estimators can help you determine the state of your wiring regarding any existing regulations.

Electrical Wiring in a Metal Building is a challenging and technical sector. SMA Estimating LLC has professional estimators whose main work is to make sure that the planning and implementation process is right. They are both professional and dedicated to providing quality services, which is why they are our right choice for any business collaboration.

Conclusion

Electrical Wiring in a Metal Building needs proper planning, good quality materials, and better execution to get a permanent, safe, and efficient source of electrical supply. Even from the initial planning and development stage, up to the time of implementing the system, no phase should be overlooked. Through collaboration with such professionals as SMA Estimating LLC, time will be saved, costs brought down and safety guaranteed.

Leave a Reply