No doubt, PCB assembly or printed circuit board assembly is more than just a technical step in creating electronic devices. It is a delicate process, where layers of minute components, invisible connections, and precision meet. If we look closely at this art of assembling printed circuit boards, we discover a complex world, where every detail matters. However, as in any technical quest, certain mistakes can disrupt this harmony and compromise the final result. This article aims to shed light on these missteps to avoid, while exploring their impact on the entire process.

What is PCB assembly?

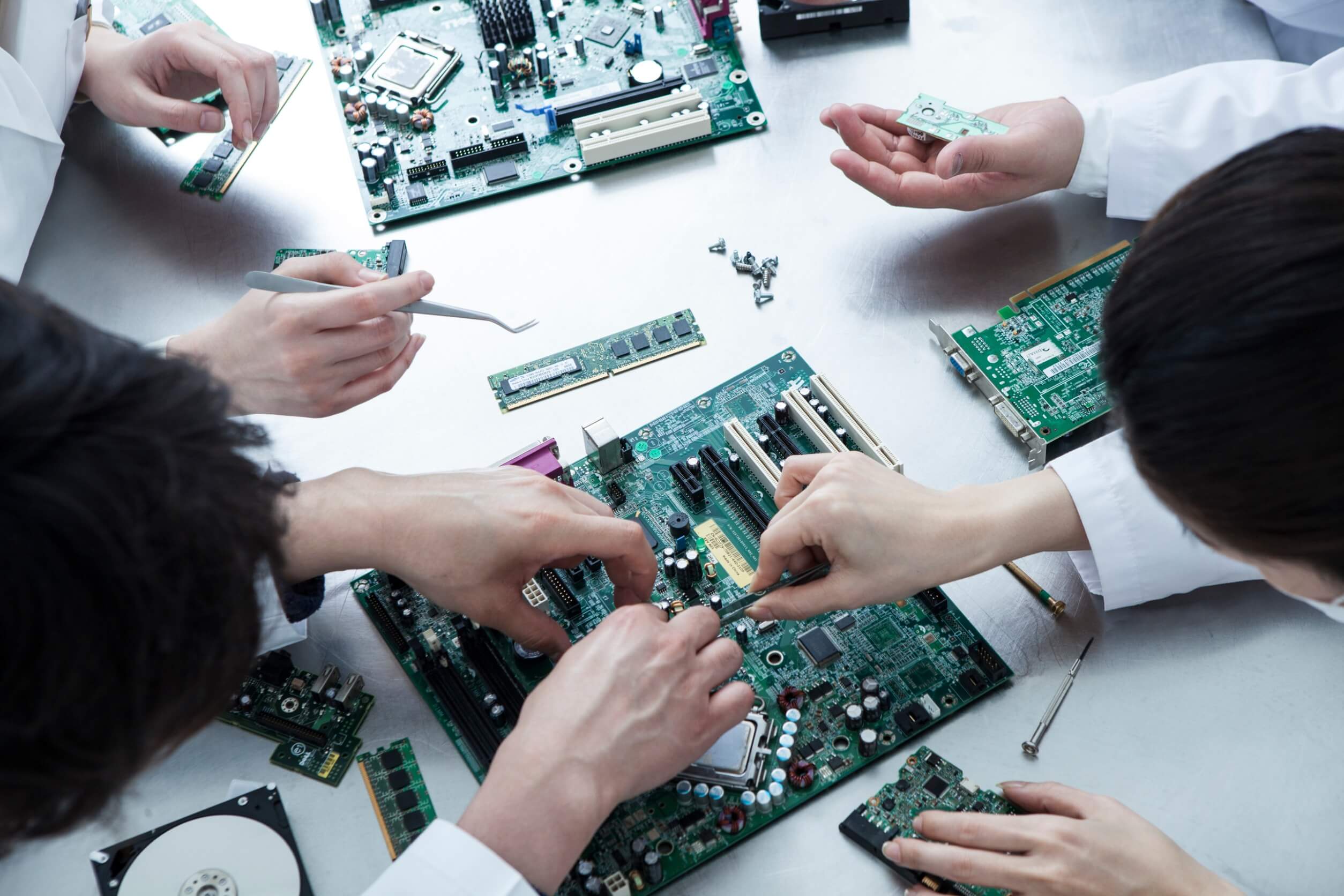

Before diving into the pitfalls to avoid, let’s take a moment to understand what PCBA actually is. These printed circuit boards sit silently at the heart of almost every modern electronic device. Our phones, computers, and even some household appliances rely on PCBs to transmit, transform, and manage electrical signals. Assembling a PCB is like creating an electronic symphony where each component plays a specific note. It involves multiple processes, such as soldering components, verifying connections, and installing specific chips. Yet, just as a symphony can be disrupted by a discordant note, the slightest mistake in PCB assembly can render a device useless or, worse, cause it to malfunction.

But why do errors occur in the assembly of these critical circuits? Often, they arise from a combination of misunderstandings, hasty decisions, and a lack of thought about the invisible but essential detail.

Common Mistakes to Avoid in PCB Assembly

- Inaccurate Design: The Beginning of Problems

The design itself is the starting point of any assembly process. If the PCB design contains flaws- such as inaccurate component dimensions or poor routing of electrical traces – it will affect everything else. A poorly designed board is like a poorly designed building; it cannot be stable.

How to avoid this?

Take the time to consider every detail during the design phase. Use specialized software to simulate the layout and ensure that each component has enough space.

- Using low-quality components

In the fascinating world of printed circuit boards, every component plays a key role. However, some may be tempted to choose lower-quality components to cut costs. This may seem like a simple decision, but these components may not deliver on their promises in terms of performance and durability.

How to avoid this?

Invest in components from trusted suppliers. If you build a good relationship with them, they will be able to guide you in your choices. Initial quality may seem expensive, but it prevents costly failures in the long run.

- Poor temperature management

If there is one invisible but powerful thing in PCB assembly, it is temperature. Excessive heat during the soldering process can damage sensitive components or even the circuit itself. Conversely, insufficient heat can lead to weak and unreliable solder joints.

How to avoid this?

Use precisely calibrated soldering equipment and follows the temperature specifications recommended by the material manufacturers.

- Human Error: The Unpredictable Factor

Even in an automated process, human error is still a possibility. Misplacement of components, incorrect soldering, or incomplete inspection can cause defects that are difficult to detect.

How to avoid this?

Incorporate a rigorous double-checking process. By automating parts of the process, you minimize human risk.

- Multilayer Stack Design Flaws

If your PCB requires multiple layers, alignment errors or non-intolerant cross-connections can lead to short circuits or disturbed signals.

How to avoid this?

Engage multilayer design experts and test each layer with scans before final assembly.

- Insufficient testing after assembly

Once assembly is complete, some people skip rigorous testing, eager to move on to the next step. Yet, an error not detected here could cost much more when a defective device reaches an end customer.

How to avoid this?

Implement multiple functional tests, including connectivity, surge, and even simulated environmental tests. Rest assured that any product shipped is flawless.

Final Thoughts

PCB assembly design is not just a technical exercise; it’s like harmonizing a precise dance, where every move has its place. By avoiding the common mistakes mentioned above, you can ensure a better end result, not only in terms of performance but also in terms of long-term satisfaction for your users.

And remember, every successful PCB builds a new bridge between the new and the familiar, between technology and utility. Take a moment to think: your next creation could be the key to an innovation that brings about tangible change.

Leave a Reply