In the world of precision engraving and marking, fiber laser engravers have become an essential tool for businesses seeking high-quality, efficient, and versatile solutions. These machines utilize a solid-state laser technology that offers exceptional accuracy, speed, and the ability to mark a wide range of materials, from metals to plastics. In this guide, we’ll explore the reasons why fiber laser engraver are transforming industries and how they can benefit your business.

What is a Fiber Laser Engraver?

A fiber laser engraver is a machine that uses a fiber laser source to engrave or mark surfaces with high precision. Unlike traditional CO2 lasers, which use gas to generate the laser beam, fiber lasers use a fiber-optic cable to produce a concentrated beam of light. This laser is absorbed more efficiently by metals, making it an ideal choice for industries that require precise engraving on materials like stainless steel, aluminum, titanium, and more.

Fiber laser engravers are widely used in industries such as automotive, jewelry, aerospace, electronics, and manufacturing. The key advantage of fiber lasers lies in their ability to mark a variety of materials with exceptional precision, speed, and minimal maintenance.

Benefits of Fiber Laser Engravers for Businesses

-

High Precision and Quality: One of the most significant advantages of fiber laser engravers is their ability to deliver extremely precise results. The concentrated beam ensures fine details and sharp edges, making them ideal for engraving intricate designs, logos, and serial numbers. This level of accuracy is essential for industries where precision is a must, such as in aerospace or electronics manufacturing.

-

Speed and Efficiency: Fiber laser engravers are known for their speed and efficiency. The high power density of the fiber laser allows for faster engraving without compromising on quality. This makes fiber lasers perfect for businesses with high production volumes or those looking to reduce turnaround times on projects.

-

Versatility Across Materials: While fiber lasers are most commonly used for metal engraving, they can also be used on a wide range of materials, including plastics, ceramics, and some composite materials. This versatility allows businesses to diversify their offerings and explore new markets. Whether you’re engraving jewelry, manufacturing parts, or creating promotional products, a fiber laser engraver can handle it all.

-

Minimal Maintenance: Fiber lasers are low-maintenance compared to other types of lasers. Since they don’t use mirrors or lenses that require frequent cleaning or alignment, they are more durable and require less upkeep. This translates into reduced downtime and maintenance costs for your business.

-

Long Lifespan: Fiber laser engravers typically have a much longer lifespan than CO2 lasers, often lasting up to 100,000 hours of operation. This durability means that the machine can continue to perform at a high level for many years, providing a strong return on investment.

-

Cost-Effectiveness: While the initial cost of a fiber laser engraver can be higher than other types of machines, the long-term benefits make them a cost-effective solution for many businesses. The speed, precision, and low maintenance requirements reduce the total cost of ownership, and the ability to work with multiple materials further enhances their value.

Key Features of Fiber Laser Engravers

When choosing a fiber laser engraver for your business, several key features should be considered:

-

Laser Power: Fiber lasers come in a range of power outputs, typically from 20W to 100W or more. The power of the laser determines how deep the engraving can be and how quickly it can be completed. Higher power lasers are suitable for engraving thicker materials or achieving deeper marks, while lower power lasers are ideal for finer, more detailed work.

-

Marking Area: The size of the engraving area is another important consideration. If you’re working with larger items or need to engrave multiple products at once, choosing a machine with a larger marking area will be beneficial. However, for smaller items or detailed work, a compact machine may be sufficient.

-

Cooling System: Fiber lasers generate a significant amount of heat during operation, so a good cooling system is essential to ensure the machine performs optimally and doesn’t overheat. Water-cooling systems are commonly used to regulate the temperature and maintain consistent performance.

-

Software Compatibility: The engraving machine should be compatible with various design software, such as AutoCAD, CorelDRAW, or Adobe Illustrator. This allows for seamless integration with your existing workflow and ensures you can easily create and import designs for engraving.

-

Automation and Integration: Depending on your business needs, you may want to consider a fiber laser engraver with automation features, such as conveyor belts, robotic arms, or integration with other production systems. This can significantly increase your production capacity and streamline your workflow.

Applications of Fiber Laser Engraving

The versatility of fiber laser engravers makes them ideal for a wide range of applications:

-

Metal Marking and Engraving: Fiber lasers excel at marking and engraving metals, making them perfect for industries such as jewelry, automotive, and aerospace. Whether you need to engrave serial numbers, logos, or intricate designs, a fiber laser provides high-quality, permanent markings on metals like stainless steel, aluminum, and titanium.

-

Plastic and Rubber Engraving: Fiber laser engravers can also mark on plastics and rubber with high precision, making them ideal for applications such as creating labels, product identification, or custom parts.

-

Medical Device Marking: Fiber lasers are commonly used in the medical industry to mark medical devices with serial numbers, barcodes, or logos. The high precision and ability to work with materials like stainless steel or titanium make them a reliable choice for this industry.

-

Electronics: Fiber lasers are widely used in the electronics industry to mark circuit boards, components, and connectors. The fine precision of the engravings ensures that the markings remain legible and durable over time.

Conclusion

Fiber laser engravers are revolutionizing the way businesses approach engraving and marking. Their combination of speed, precision, versatility, and low maintenance makes them an invaluable asset for industries ranging from jewelry to aerospace. By investing in a fiber laser engraver, businesses can enhance product offerings, improve production efficiency, and stay ahead of the competition.

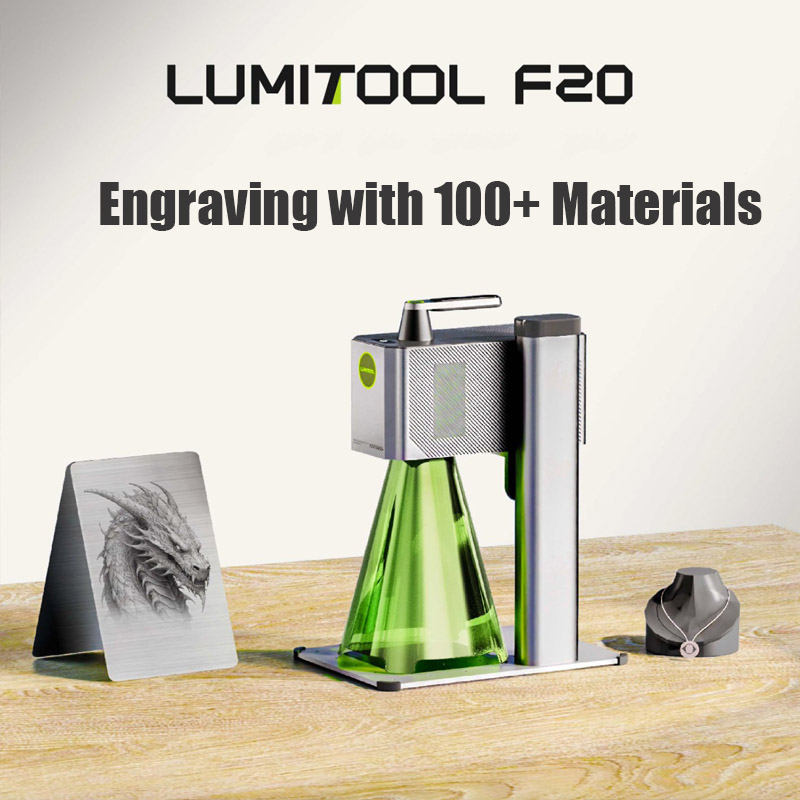

For businesses looking to explore fiber laser technology, the Lumitoool Optical Fiber Laser Marking Machine offers a top-tier solution. With cutting-edge technology and outstanding support, it’s the perfect tool for businesses looking to take their engraving capabilities to the next level.

Leave a Reply