Vacuum form plastic sheets are versatile materials, utilized in various industries for their adaptability, cost-effectiveness, and durability. In this article, we will explore what Vacuform plastic sheets are, how they’re made, their diverse applications, and their benefits. Let’s dive in to discover more about this remarkable material!

Introduction to Vacuum Form Plastic Sheets

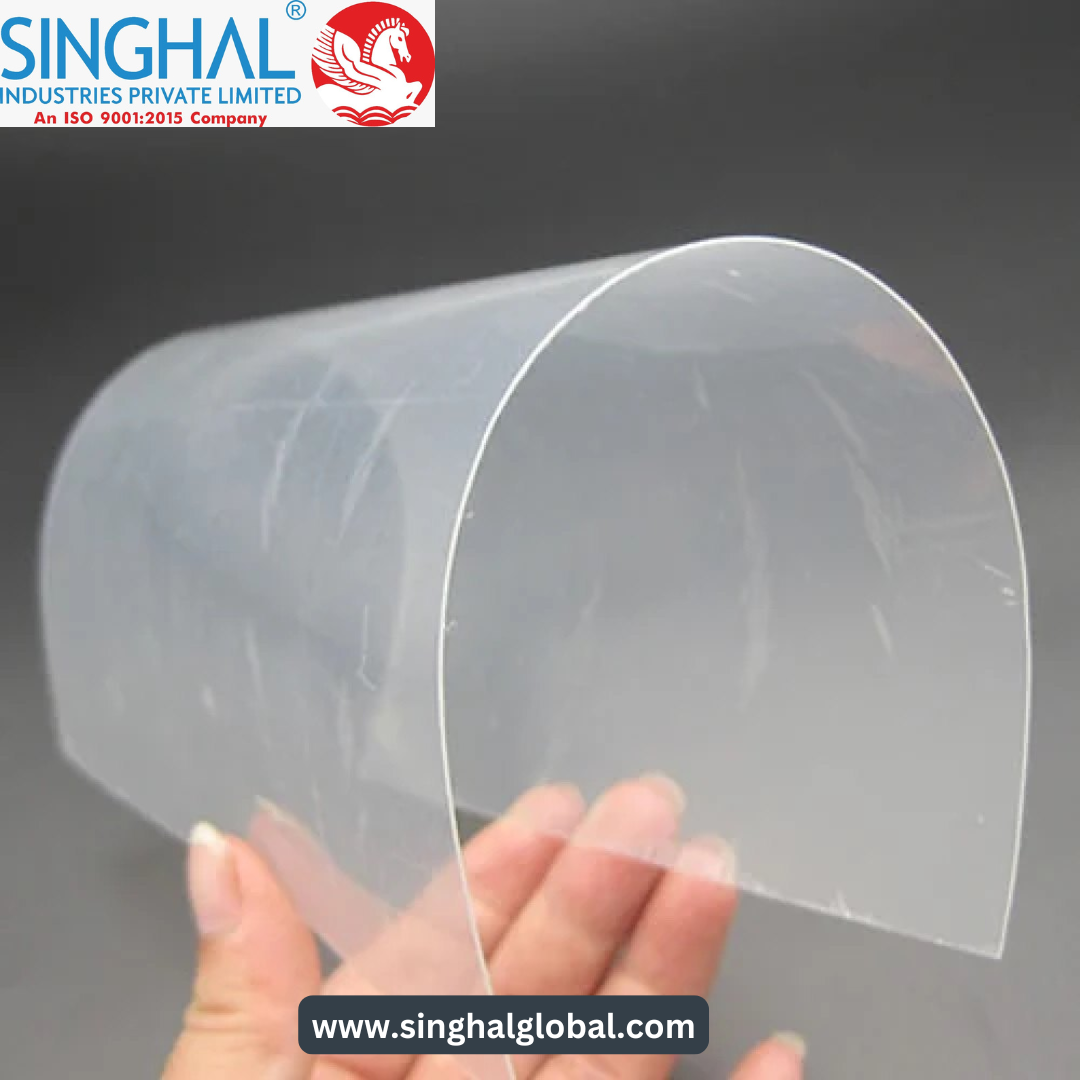

Vacuum form plastic sheets are created through the vacuum forming process, which involves heating a plastic sheet until it’s pliable, then shaping it against a mold by applying vacuum pressure. This method allows for the creation of lightweight yet strong products with complex shapes.

What Are Vacuum Form Plastic Sheets?

In vacuum forming, different plastics can be used, such as ABS (Acrylonitrile Butadiene Styrene), HIPS (High Impact Polystyrene), and PETG (Polyethylene Terephthalate Glycol). Each of these materials has unique characteristics that make them suitable for specific applications, from automotive parts to medical devices.

The Vacuum Forming Process Explained

The vacuum forming process is an efficient method for shaping plastic sheets into specific forms. Here’s how it works, step by step:

- Material Preparation: The process begins with selecting the appropriate plastic sheet, which is usually around 1/8 inch thick. Common materials include ABS, HIPS, and PETG, each chosen for their unique properties.

- Heating: The plastic sheet is heated in an oven until it becomes soft and pliable. This heating process can take several minutes, depending on the thickness and type of material used.

- Molding: Once the sheet is sufficiently heated, it is quickly moved to a mold. The mold can be made from various materials such as aluminum or wood and is designed to the specifications of the desired final product.

- Vacuum Application: A vacuum is applied to the mold, pulling the soft plastic down onto the mold’s surface. The vacuum creates a seal, ensuring the plastic forms tightly around the mold’s contours.

- Cooling: After the vacuum has been applied, the plastic is allowed to cool and solidify in its new shape. This cooling phase is crucial as it locks in the details of the mold.

- Trimming: Once cooled, the formed plastic sheet is removed from the mold. Any excess material around the edges is trimmed away to achieve the final dimensions.

- Finishing Touches: Additional finishing processes may include surface treatments, printing, or the application of protective coatings.

This process is not only efficient but also highly versatile, making it suitable for a wide range of applications across various industries.

Types of Vacuum Form Plastic Sheets

Vacuum form plastic sheets come in various types, each suitable for different applications. Below are some of the most common materials used in vacuum forming:

- Acrylonitrile Butadiene Styrene (ABS): Known for its strength and durability, ABS is widely used in automotive parts, toys, and consumer products. It is resistant to impact and heat, making it a preferred choice for various applications.

- High Impact Polystyrene (HIPS): This material is known for its ease of fabrication and is often used in packaging and display products. HIPS sheets can be easily printed on, making them ideal for marketing materials.

- Polyethylene Terephthalate Glycol (PETG): PETG offers excellent clarity and is often used for applications requiring transparency, such as display cases and medical packaging. It is also resistant to impact and can be easily thermoformed.

- Polyvinyl Chloride (PVC): PVC sheets are cost-effective and widely used in various industries. They are durable and can be used for signage, displays, and packaging solutions.

Each type of vacuum form plastic sheet has its unique properties, making it essential to select the right one for your specific needs.

Choosing the Right Vacuum Form Plastic Sheet

When selecting a vacuum form plastic sheet, consider the following factors:

- Material Properties: Understand the properties of different materials, including strength, flexibility, and temperature resistance. This knowledge will help you choose the best material for your application.

- Thickness: The thickness of the sheet can significantly impact its performance. Thicker sheets tend to be stronger but may be more challenging to form. Conversely, thinner sheets are easier to shape but may lack durability.

- Application Requirements: Consider the specific needs of your application, such as transparency, impact resistance, or surface finish. Different applications will require different material characteristics.

- Cost: Budget considerations can influence your choice of material. While some materials may be more expensive, their performance benefits may justify the higher cost.

- Lead Time: If you need the product quickly, be mindful of lead times associated with specific materials and manufacturing processes.

By carefully evaluating these factors, you can select the most suitable Vacuum forming plastic sheet suppliers for your project.

Applications of Vacuum Form Plastic Sheets

Vacuum form plastic sheets are incredibly versatile, finding applications across a wide array of industries. Here are some common uses:

- Packaging: Vacuum forming is commonly used in the packaging industry for products such as food trays, clamshells, and protective packaging for electronics. The ability to create custom shapes helps protect products during shipping and handling.

- Automotive: In the automotive industry, vacuum-formed plastic sheets are used for interior components such as dashboards, door panels, and trims. The lightweight nature of these components contributes to overall fuel efficiency.

- Medical: Vacuum forming is vital in the medical field, where it is used to create trays, protective equipment, and custom molds for various applications. The ability to create sterile packaging is crucial in this industry.

- Retail Displays: Retailers utilize vacuum-formed plastic sheets to create eye-catching displays for their products. The ability to customize shapes and sizes allows for unique marketing solutions that attract customers.

- Consumer Products: Many consumer products, such as toys and household items, are made using vacuum-formed plastic sheets. This method allows for mass production while maintaining quality and detail.

The versatility of vacuum form plastic sheets makes them an essential material across numerous sectors.

Benefits of Using Vacuum Form Plastic Sheets

The use of vacuum form plastic sheets offers numerous advantages:

- Cost-Effectiveness: Vacuum forming is a relatively low-cost method for producing plastic parts, especially in large quantities. This affordability makes it accessible for small and large businesses alike.

- Design Flexibility: The vacuum forming process allows for intricate designs and shapes, providing manufacturers with the ability to create complex components that meet specific design criteria.

- Durability: Vacuum-formed plastic sheets are known for their strength and resilience. They can withstand various environmental conditions, making them suitable for both indoor and outdoor applications.

- Lightweight: Compared to materials like metal or glass, vacuum form plastic sheets are significantly lighter, which can reduce shipping costs and improve product handling.

- Quick Turnaround: The vacuum forming process allows for faster production times compared to other methods, enabling businesses to bring products to market quickly.

Challenges in Vacuum Forming Plastic Sheets

Despite its advantages, vacuum forming comes with challenges:

- Material Limitations: Not all plastic materials can be easily vacuum-formed. Some may require specific conditions or may not perform well under vacuum pressure.

- Precision: Achieving high precision in complex designs can be challenging. Minor errors during the molding process can lead to defects in the final product.

- Post-Processing Needs: Some vacuum-formed products may require additional finishing processes, such as trimming or painting, which can add to production time and cost.

- Skill Requirement: Successful vacuum forming requires skilled operators familiar with the machinery and processes. Lack of expertise can lead to production inefficiencies.

By understanding these challenges, businesses can take proactive measures to mitigate potential issues during the vacuum forming process.

Innovations in Vacuum Form Plastic Sheets

As technology advances, so do the techniques and materials used in vacuum forming:

- Advanced Materials: New materials are being developed that offer enhanced properties, such as better impact resistance and flexibility, which can broaden the application of vacuum-formed products.

- Sustainable Practices: Many manufacturers are now focusing on sustainability by using recycled materials and exploring eco-friendly practices in the vacuum forming process.

- Automation: Automation technology is being integrated into the vacuum forming process, improving production efficiency and reducing human error.

- 3D Printing: The integration of 3D printing in creating molds for vacuum forming is an emerging trend. This allows for rapid prototyping and custom molds that can be produced quickly and cost-effectively.

These innovations are reshaping the vacuum forming industry, making it more efficient and environmentally friendly.

How to Maintain and Store Vacuum Form Plastic Sheets

To ensure the longevity and performance of vacuum form plastic sheets, proper maintenance and storage are essential:

- Storage Conditions: Store sheets in a cool, dry place away from direct sunlight. Excessive heat or UV exposure can warp or degrade the material over time.

- Handling: When handling vacuum form plastic sheets, wear gloves to avoid transferring oils from your skin, which can affect adhesion during later processing.

- Cleaning: Use a mild detergent and water for cleaning. Avoid harsh chemicals that may damage the plastic surface.

- Inspection: Regularly inspect sheets for any signs of damage or wear, especially before use in production.

By following these maintenance tips, you can ensure that your vacuum form plastic sheets remain in excellent condition for years to come.

Comparing Vacuum Forming with Other Plastic Forming Methods

Vacuum forming is just one of several methods for shaping plastics. Here’s how it compares with other techniques:

- Injection Molding: Unlike vacuum forming, which shapes a sheet over a mold, injection molding injects molten plastic into a mold. This method is more suited for high-precision parts but has higher startup costs.

- Thermoforming: Similar to vacuum forming, thermoforming involves heating plastic sheets, but it doesn’t necessarily use vacuum pressure. This method can be less precise but is often faster for simpler shapes.

- Blow Molding: This technique is primarily used for hollow objects like bottles. It involves inflating molten plastic within a mold, differing significantly from the vacuum forming process.

Understanding these differences can help manufacturers choose the most suitable method for their specific needs.

Vacuum Forming for DIY Projects

For hobbyists and DIY enthusiasts, Vacuum form plastic sheets can be an exciting and rewarding project. Here are some popular DIY applications:

- Custom Molds: Create custom molds for various projects, from model making to crafting unique components for toys or models.

- Packaging Solutions: Design and produce your own packaging solutions for items you sell or create, ensuring a professional look.

- Theatrical Props: Use vacuum forming to create realistic props for theater productions, enhancing the visual impact of performances.

- Home Decor: Experiment with different shapes and designs to create unique home decor items that stand out.

Conclusion

Vacuum form plastic sheets play a crucial role in various industries, offering versatility, durability, and cost-effectiveness. Understanding the vacuum forming process, material options, applications, and maintenance practices can help businesses and individuals alike make the most of this innovative manufacturing technique. As technology continues to evolve, the future of vacuum forming looks promising, paving the way for even more exciting applications and sustainable practices. Whether for commercial use or personal projects, vacuum forming provides a world of possibilities limited only by imagination.

FAQs

What materials are commonly used in vacuum forming?

Common materials include ABS, HIPS, PETG, and PVC, each chosen for their specific properties.

Can vacuum forming be used for small production runs?

Yes, vacuum forming is cost-effective for both small and large production runs, making it suitable for various applications.

What are the main advantages of vacuum forming?

Advantages include cost-effectiveness, design flexibility, durability, lightweight materials, and quick turnaround times.

How do I maintain vacuum form plastic sheets?

Store them in a cool, dry place away from sunlight, handle them with care, clean with mild detergent, and regularly inspect for damage.

Is vacuum forming suitable for complex designs?

Vacuum forming can handle complex designs, although high precision may be more challenging compared to other methods like injection molding.

Leave a Reply