Introduction

A Phosphorus Triiodide Manufacturing Plant Project Report provides a detailed guide for setting up a facility to produce phosphorus triiodide (PI₃). This compound, a red or reddish-brown solid, is primarily used as a reagent in organic synthesis, particularly for converting alcohols into alkyl iodides. With its importance in chemical research and pharmaceutical industries, the production of phosphorus triiodide offers a promising business opportunity.

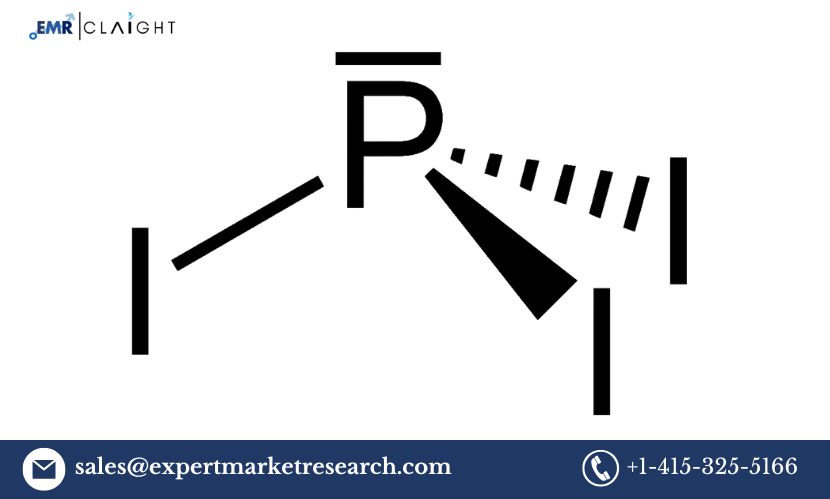

Overview of Phosphorus Triiodide

Phosphorus triiodide is a chemical compound composed of phosphorus and iodine. It is sensitive to moisture and reacts with water to release hydrogen iodide. Due to its reactive properties, PI₃ is widely used in various chemical processes, especially in organic synthesis.

Key Uses of Phosphorus Triiodide:

- Organic Synthesis: Conversion of alcohols into alkyl iodides.

- Pharmaceuticals: Used in drug development and chemical intermediates.

- Laboratory Reagent: Commonly used in research for iodination reactions.

Raw Materials

The primary raw materials required for manufacturing phosphorus triiodide are:

- Red or White Phosphorus: A crucial element for the reaction.

- Iodine: Reacts with phosphorus to form phosphorus triiodide.

- Solvents: Such as benzene or other inert organic solvents, used during the reaction process.

Sourcing high-purity raw materials is essential for producing high-quality phosphorus triiodide.

Get a Free Sample Report with Table of Contents@

Manufacturing Process

The production of phosphorus triiodide involves the following steps:

Step 1: Preparation of Reactants

- Phosphorus is weighed and introduced into a reaction vessel under controlled conditions.

- Iodine is added in a stoichiometric ratio to ensure complete reaction.

Step 2: Reaction

- The mixture is heated under an inert atmosphere (e.g., nitrogen or argon) to prevent unwanted side reactions.

- Phosphorus reacts with iodine to form phosphorus triiodide:

P₄ + 6I₂ → 4PI₃

Step 3: Purification

- The crude phosphorus triiodide is purified by sublimation or recrystallization to remove impurities.

Step 4: Packaging

- The purified product is packed in airtight, moisture-resistant containers to prevent degradation.

Equipment and Machinery

The following equipment is required for manufacturing phosphorus triiodide:

- Reaction Vessels: Made of corrosion-resistant materials to handle iodine.

- Heating Systems: For controlled reaction conditions.

- Inert Gas Systems: To maintain an oxygen-free environment.

- Filtration Units: For removing impurities during purification.

- Packaging Equipment: For airtight and safe packaging of the final product.

Market Applications and Demand

Phosphorus triiodide has a niche yet growing market. Its demand is driven by:

- Chemical Industry: Used in producing various iodinated compounds.

- Pharmaceuticals: Plays a role in the synthesis of drug intermediates.

- Research and Development: High demand in academic and industrial research laboratories.

As the pharmaceutical and chemical sectors expand globally, the market for phosphorus triiodide is expected to grow steadily.

Financial Considerations

Startup Costs

- Land and Infrastructure: Setting up a plant with proper ventilation and safety measures.

- Equipment Investment: Procuring high-quality, corrosion-resistant machinery.

- Initial Inventory: Stocking raw materials like phosphorus and iodine.

Operating Costs

- Raw materials, utilities (electricity and inert gases), labor, and maintenance expenses.

Revenue Potential

The profitability depends on market demand, production efficiency, and quality of the product. Establishing partnerships with pharmaceutical and chemical companies can ensure steady sales.

Safety and Regulatory Compliance

Phosphorus triiodide manufacturing involves handling hazardous chemicals, necessitating strict adherence to safety and environmental regulations. Key considerations include:

- Personal Protective Equipment (PPE): Mandatory for workers handling phosphorus and iodine.

- Ventilation Systems: To prevent exposure to fumes.

- Waste Management: Proper disposal of chemical waste to avoid environmental contamination.

- Regulatory Approvals: Compliance with local and international chemical safety standards.

Marketing Strategies

To succeed in this niche market, consider the following strategies:

- Targeted Outreach: Focus on pharmaceutical and chemical companies.

- Quality Assurance: Highlight the purity and reliability of your product.

- Eco-Friendly Practices: Promote sustainable manufacturing methods.

- Distribution Channels: Partner with industrial suppliers and online distributors.

FAQ

1. What is phosphorus triiodide used for?

Phosphorus triiodide is primarily used in organic synthesis, pharmaceuticals, and as a laboratory reagent for iodination reactions.

2. What raw materials are required for its production?

The key raw materials are red or white phosphorus, iodine, and inert solvents.

3. What are the safety precautions in manufacturing phosphorus triiodide?

Manufacturing requires proper ventilation, PPE for workers, and adherence to chemical safety regulations to handle hazardous materials.

4. How can a phosphorus triiodide plant be profitable?

Profitability depends on efficient production, market demand, and building strong relationships with industrial buyers.

5. What industries require phosphorus triiodide?

The chemical, pharmaceutical, and research sectors are the primary consumers of phosphorus triiodide.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

Leave a Reply